Single Batch:

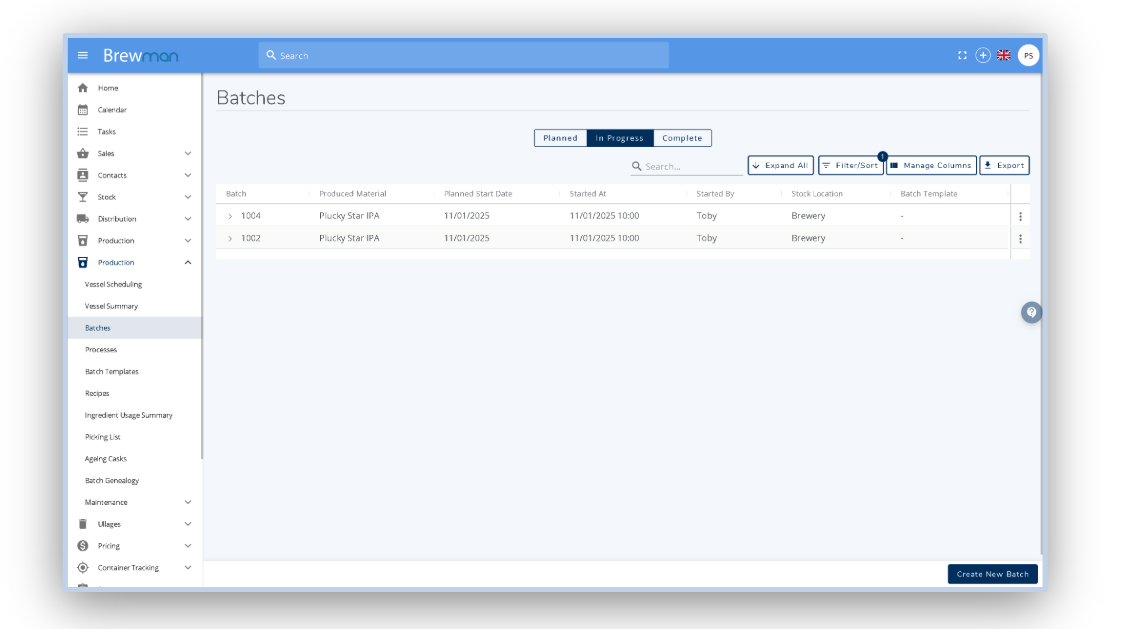

To begin a single batch you will need to go to Production and then start your batch from your preferred option found in this guide: https://features.premiersystems.com/admin/kb/a/batch-production-how-to-start-a-batch/en

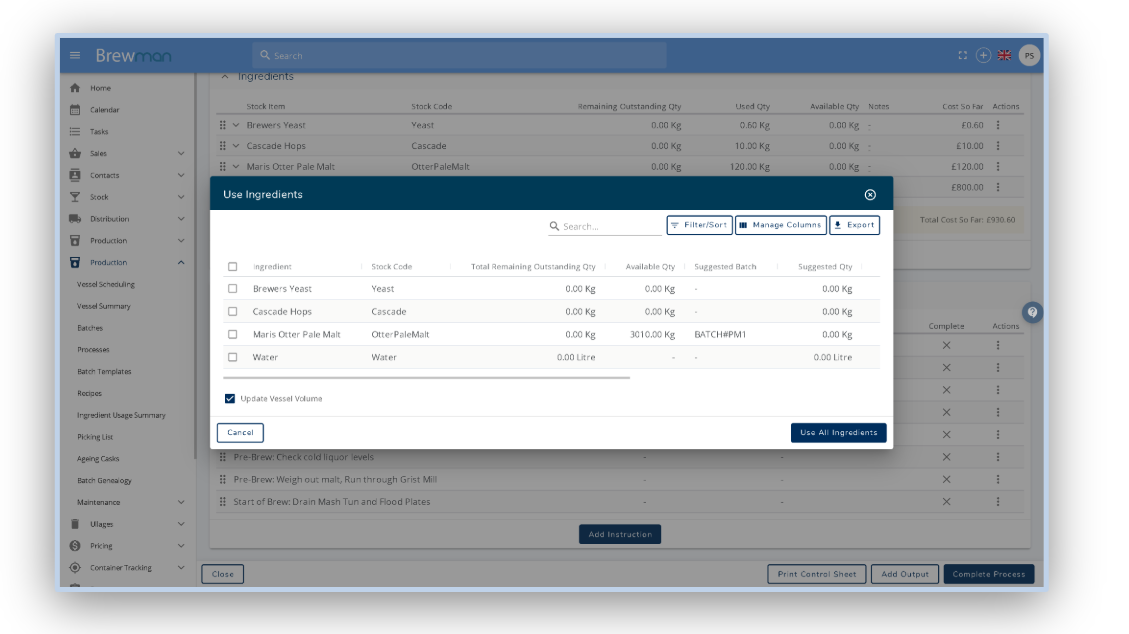

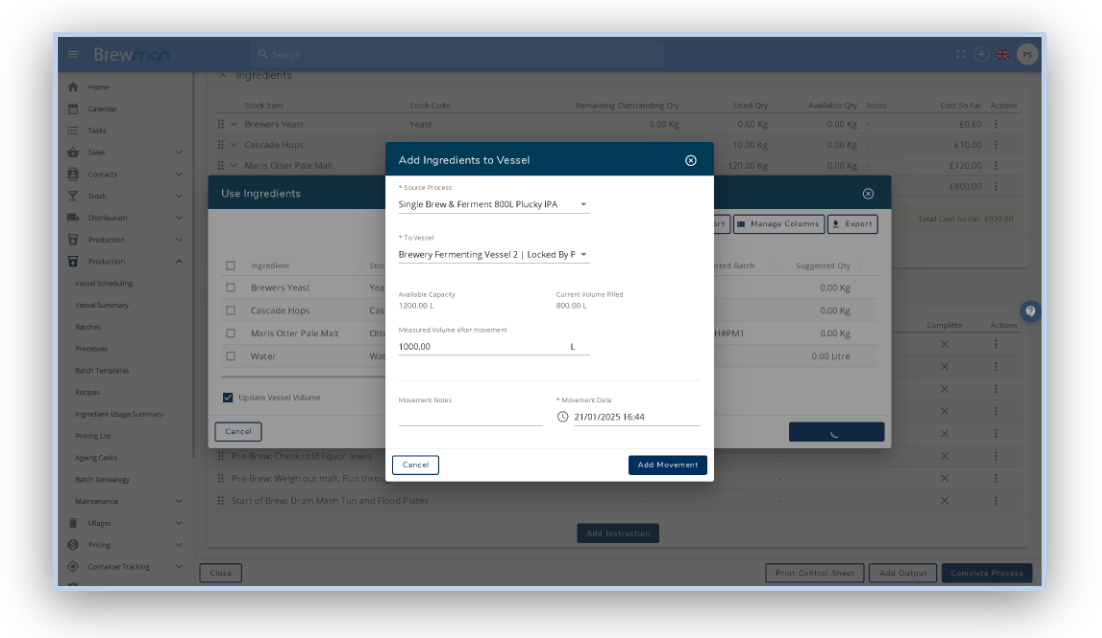

Once you have started your batch, you will then need to bulk use your ingredients for your first process and update the vessel volume through the toggle.

This will allow you to update the amount of liquid in the vessel upon using your ingredients.

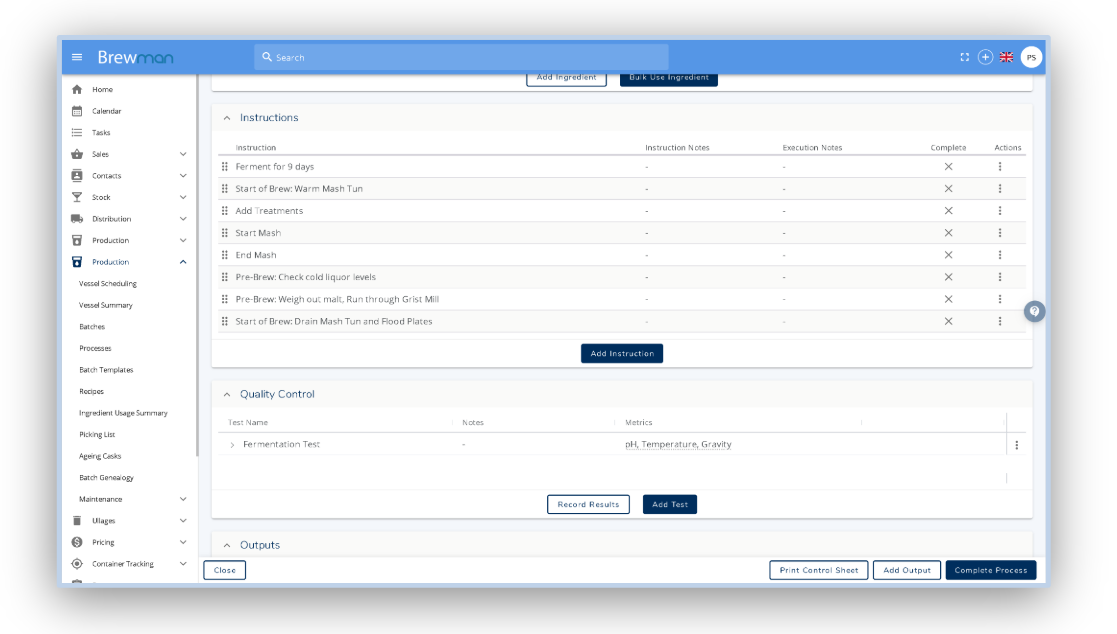

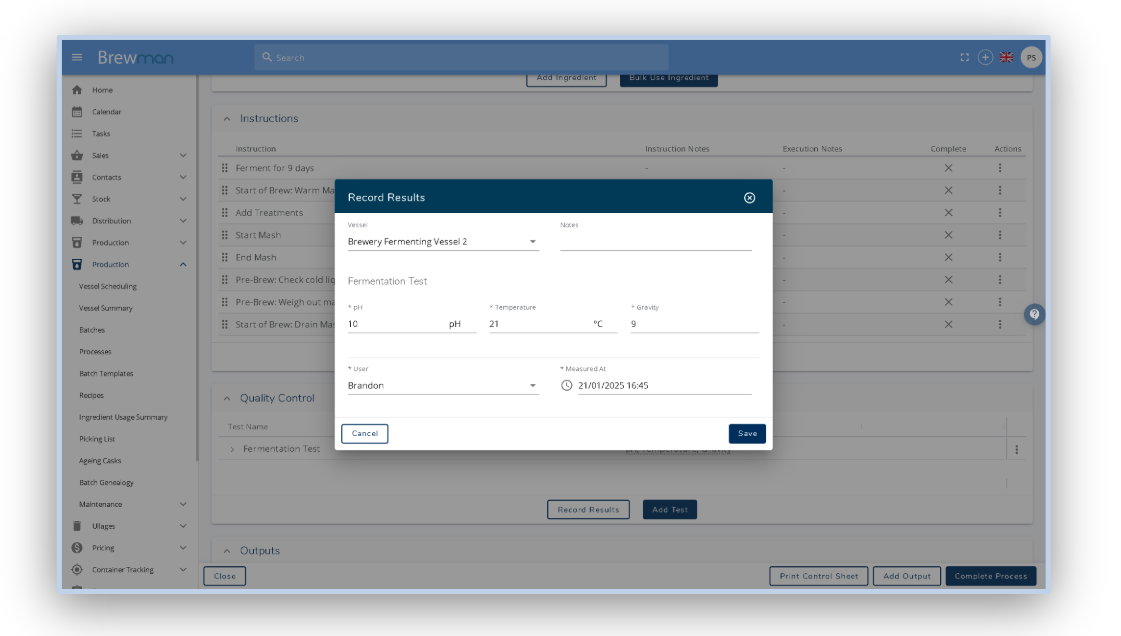

Once liquid is in vessels, your next steps would be to work through any instructions you have set up on your recipe (reflecting this in BrewMan as you complete them) and then record any QC tests that you wish to gather data on.

To do this, scroll to the Quality Control Tests field and select to record results. This will then ask you what vessel you would like to record these QC tests against.

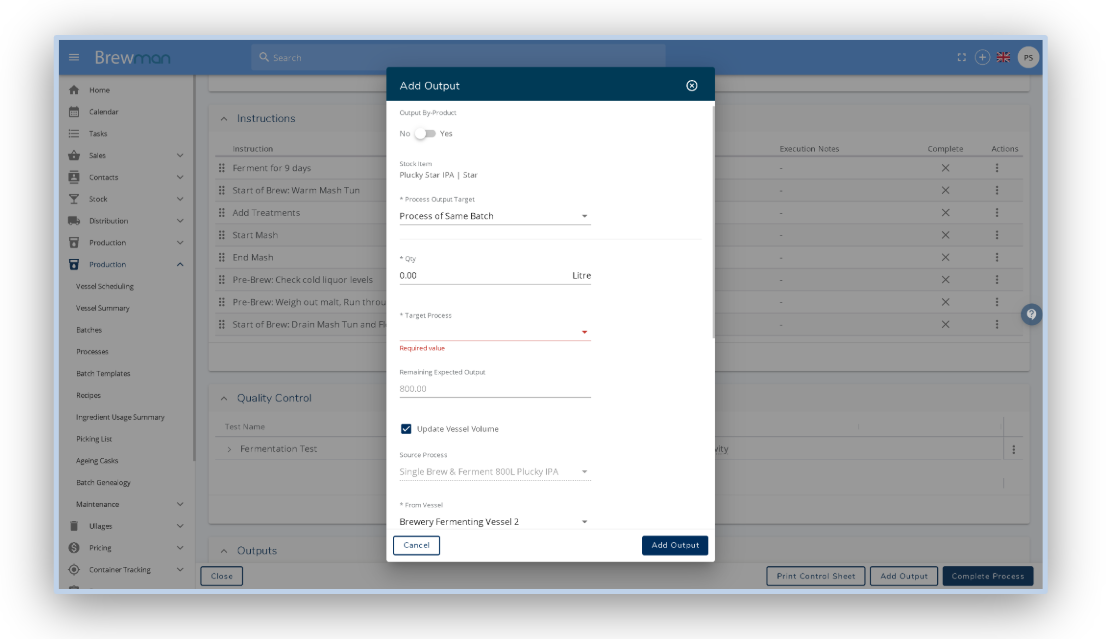

Upon completion of your QC test recording, your next steps would be to push this liquid through its varying processes. For example, these could be processes such as a Wort, Ferment and Hold.

To do this you will need to add an output from the first process and decide the process it is moving into. Please refer to https://features.premiersystems.com/admin/kb/a/batch-production-how-to-add-outputs/en for any further information on outputting.

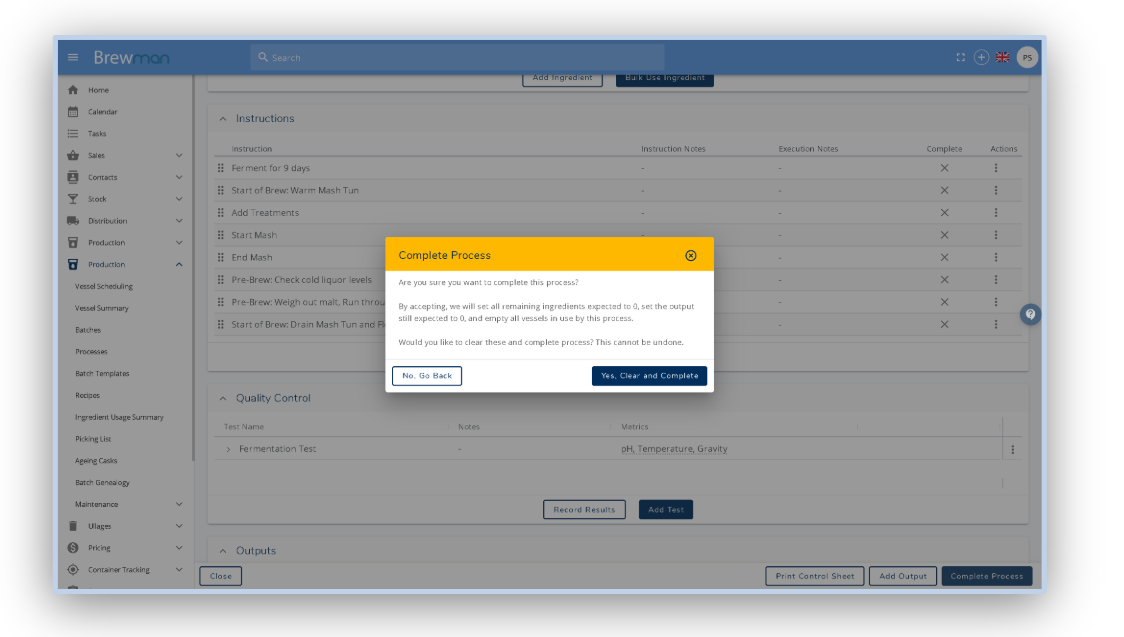

Once all liquid has been moved from the first process, this is now in a stage where it is ready to be marked as complete.

You will then repeat the above for the remaining processes until the liquid has made its way through each of your treatment processes and it is now ready to be packaged.

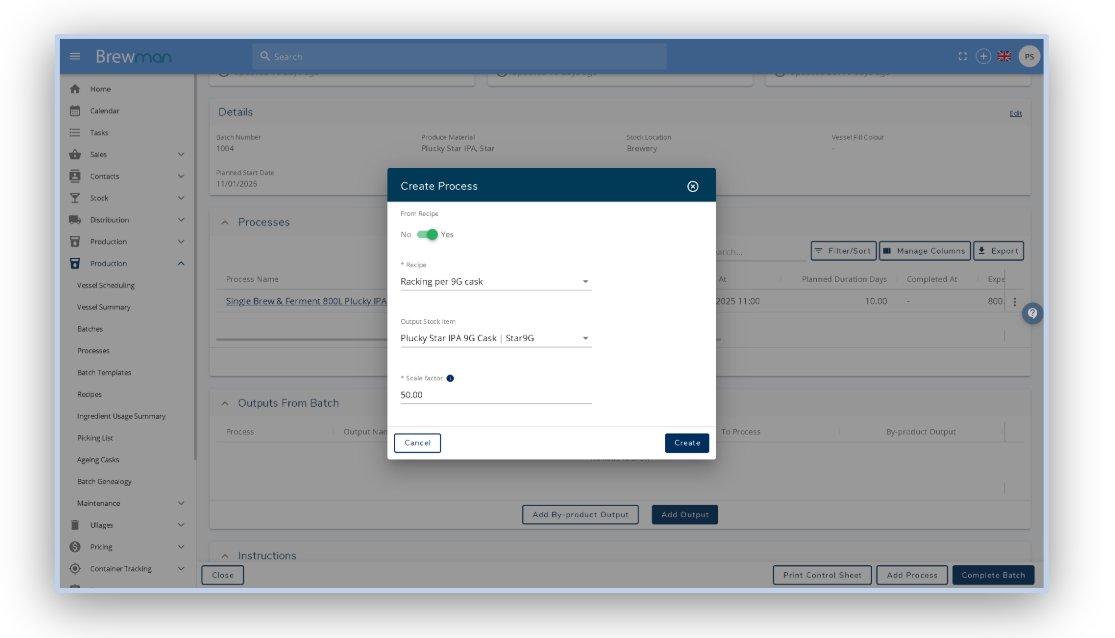

Now that it is ready for packaging you will need to add another process to your batch for the packaging type it is going into. Please refer to https://features.premiersystems.com/admin/kb/a/batch-production-how-to-add-processes-to-in-progress-batches/en for further information on adding a new process.

This liquid can now be moved from the last treatment process into the newly added packaging process via outputs. Now that you have the liquid in the packaging process you will need to use your remaining ingredients.

The last steps of this process would be to take any final recordings of QC tests and instruction completion before outputting this packaged product to stock.

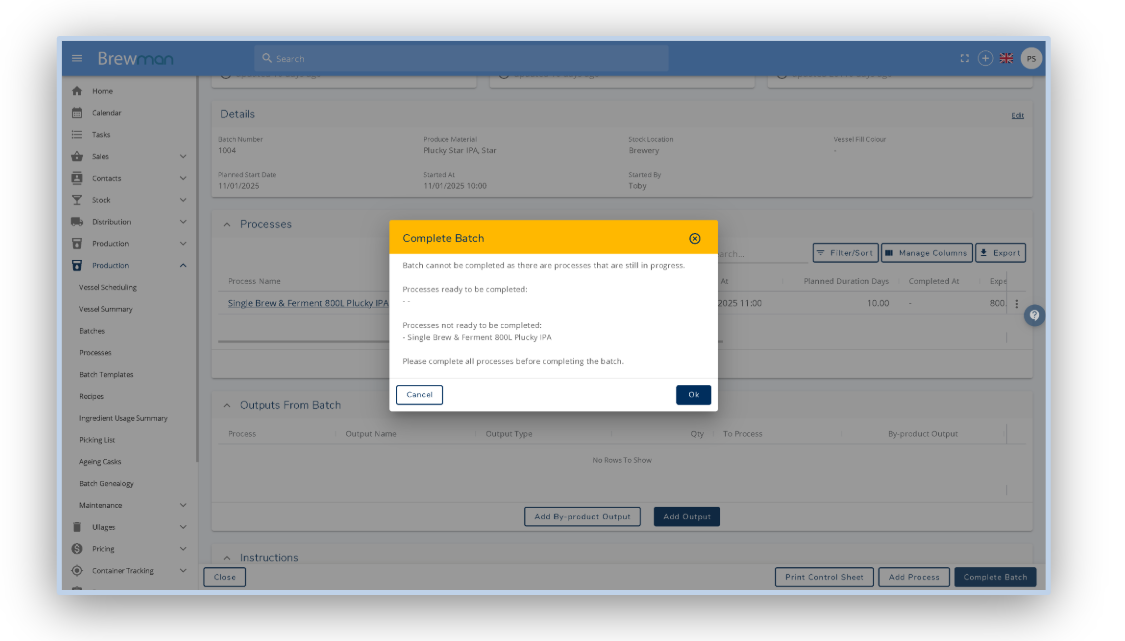

The final action is to then complete any uncompleted processes and mark the batch as complete.

Was this helpful?

Comments

You must be logged in to comment in this article.

Login to comment