Stock Requirements will allow you to see if you have enough Materials/Products to produce your planned Batches. It will also highlight shortfalls and help produce Purchase Orders if required.

Go to Stock → Stock Requirements.

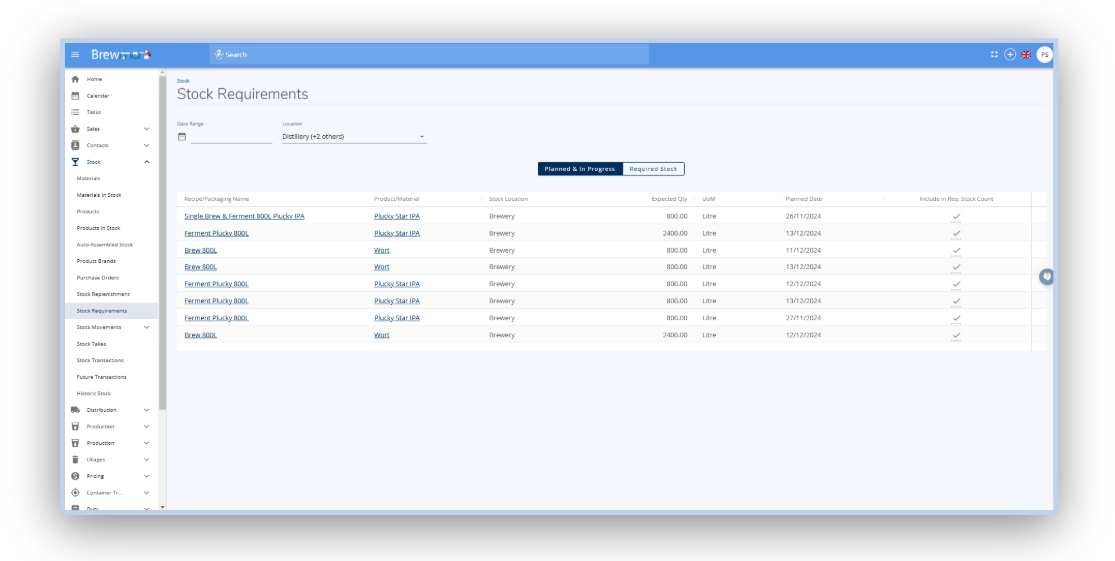

By default, the list will show all your Planned and In Progress Processes. These can be added into the system in Production by creating a new Batch with a Planned Start Date.

You can filter the list by selecting a Date Range and a Stock Location you wish to view.

If you wish to remove a Planned Recipe/Packaging from the requirements, click on the tick box on the relevant row under Include in Req. Stock Count and select No.

When you are ready, click the Required Stock tab to view the Requirements.

Required Stock

This tab should now display:

All the Products/Materials needed to fulfil your processes, grouped by Supplier.

The Stock Location where the item is required.

The current In Stock figure of each Material/Product needed and how much is On Order through Purchase Orders on the system.

The Required Quantity needed to produce the Processes.

The amount of Remaining Stock there will be after producing the Processes.

If there is insufficient items In Stock and On Order combined, the Shortfall will highlight how much more is required.

The Available to Transfer column will highlight if there is any of the Material/Product in a different Stock Location.

The Earliest Date Req will show highlight when the Material/Product is needed for Processes.

The Lead Time is taken from the Purchasing Details of the Material/Product. This will highlight the estimated arrival time.

If a Shortfall is highlighted or if there is a low level of Stock Remaining, you may wish to create a Purchase Orders for the items.

Click Create PO, this will create a Purchase Order for all items that have a Shortfall. Alternatively, tick the boxes next to each item you wish to order and click Create PO for Selected.

You can View, Edit and then Email this to the Supplier. For more information on Purchase Orders click here.

Was this helpful?

Comments

You must be logged in to comment in this article.

Login to comment